Mill

There are many grinding technologies depending on product characteristics and customer specifications (particle size, density, flow rate, etc.).

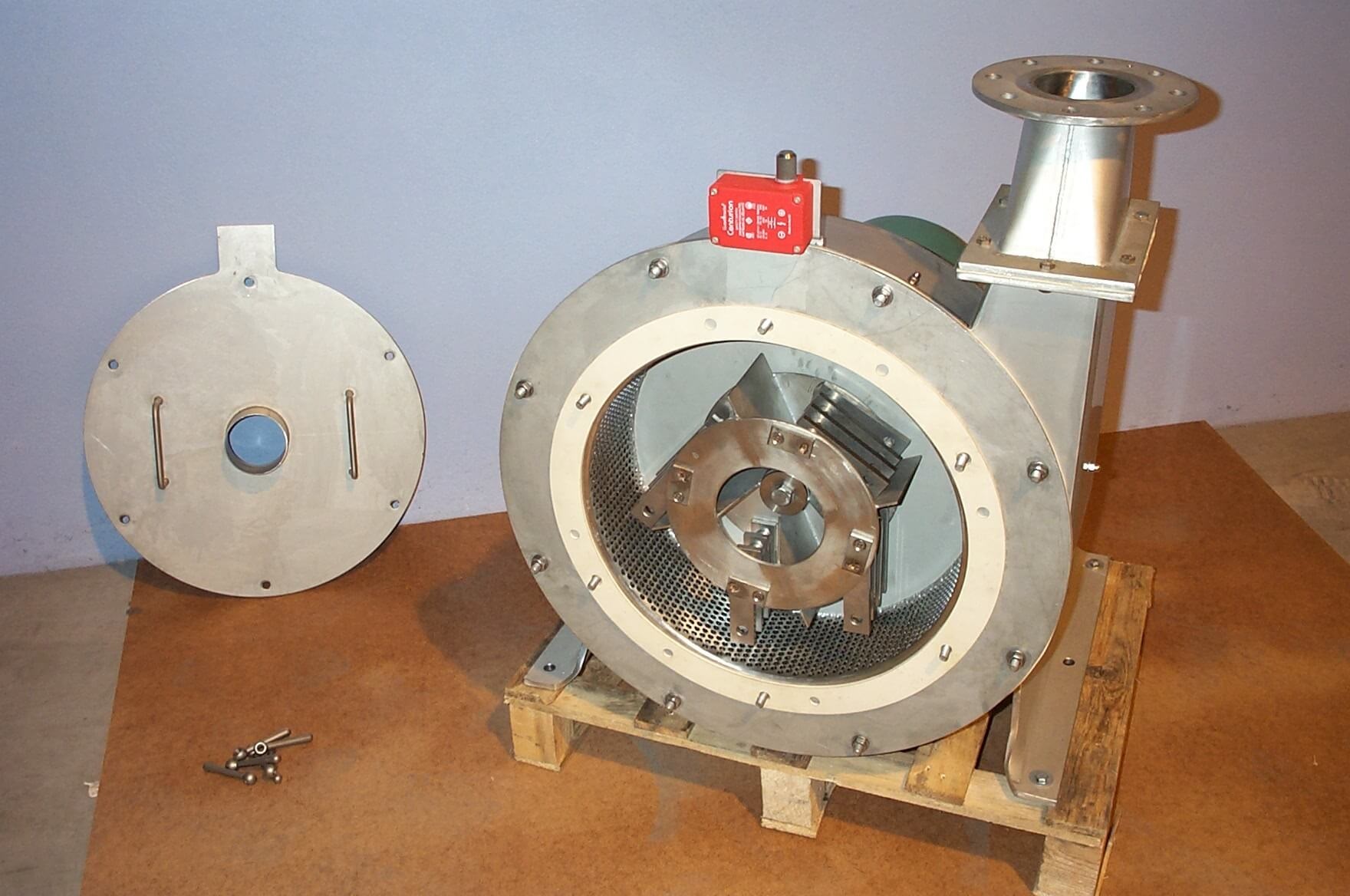

CROIX designs and manufactures the most widely used model in the industry, the hammer mill.

It consists:

– A rotor, equipped with removable hammers

– A stator equipped with a perforated grid through which the product passes

The product is introduced into the center of the moving rotor. The centrifugal force projects the powder which hits the moving hammers. It is then pulverized and projected towards the sieving grid. The grid allows grains of the required size to pass through and repels particles that have not been sufficiently crushed.

This technology has two advantages: Easy maintenance of the hammers when they are worn, rapid replacement of the sieving grid to modify the particle size of the ground material that we wish to obtain.

If this technology does not meet your needs, CROIX will be happy to direct you to our partners and integrate the chosen solution.

- Food

- Other industries

- Pet food

- Steel

- Stainless steel 304 L

- Stainless steel 316 L

- Stripped

- Sanded

- RA < 0.8 µ

- Electropolished